COMPANY ADVANTAGE

COMPANY ADVANTAGE

Range 10+

Countries

| Annual 25%+

Growth

|

|

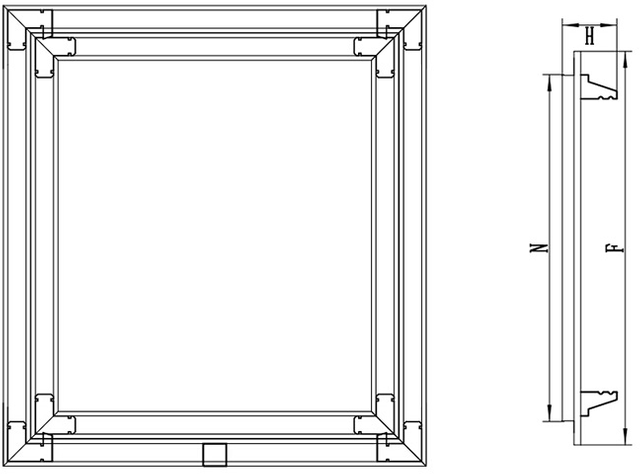

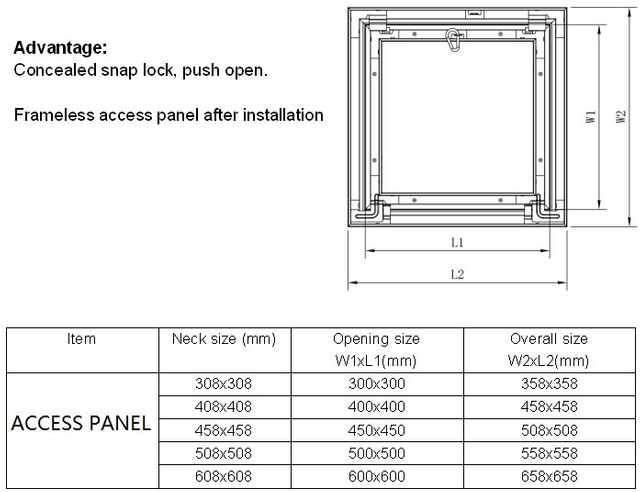

TECHNICAL PARAMETER

JIAXING VTH TECHNOLOGIES CO.,LTD.

TECHNICAL PARAMETER

JIAXING VTH TECHNOLOGIES CO.,LTD.Product model: D01F

Type:Access panel

Access Panel (with gypsum board)

Detailed description

Access Panel provide a protected gypsum board faced low profile access solutions through gypsum board walls and ceilings for access to building engineering services where space is at a premium. The narrow 24 mm profile produces a lightweight, robust solution that can be used in all types of wall or ceiling construction.

The panels consist of a gypsum board faced pivoting door tray and frame with a push catch or square drive operated lock finished in oxidation which can be over painted on site with emulsion to blend with the surrounding surface.

The door tray encapsulates a layer of 12.5/9.5 mm plasterboard with a simulated beaded edge to the frame and door tray acting as a key for the tape and joint or skim coat.

These panels must be fitted prior to wet trades so the metal beaded frame parts of the door and frame can be incorporated into the ceiling or wall membrane in the same way as a conventional perforated corner or stop bead.

To fully finish the look specify either the touch catch or if a lock is required opt for the ‘close the click’option.

Product guidance - As Standard

Finish: Factory finished Oxidation

Optional size: 200x200mm; 300x300mm; 400x400mm; 500x500mm; 600x600mm; 450x450mm; 600x300mm; 800x400mm; 800x800mm; 900x600mm; 1200x600mm.

The panels consist of a gypsum board faced pivoting door tray and frame with a push catch or square drive operated lock finished in oxidation which can be over painted on site with emulsion to blend with the surrounding surface.

The door tray encapsulates a layer of 12.5/9.5 mm plasterboard with a simulated beaded edge to the frame and door tray acting as a key for the tape and joint or skim coat.

These panels must be fitted prior to wet trades so the metal beaded frame parts of the door and frame can be incorporated into the ceiling or wall membrane in the same way as a conventional perforated corner or stop bead.

To fully finish the look specify either the touch catch or if a lock is required opt for the ‘close the click’option.

Product guidance - As Standard

Finish: Factory finished Oxidation

Optional size: 200x200mm; 300x300mm; 400x400mm; 500x500mm; 600x600mm; 450x450mm; 600x300mm; 800x400mm; 800x800mm; 900x600mm; 1200x600mm.

+86-573-83711140 / Mobile: +86-13738274179

+86-573-83711140 / Mobile: +86-13738274179